No. 77-2-4,No.13 Road,Shenyang Economic And Technological Development Zone,Liaoning Province,China.

Telephone:+86-130 32458698

No. 77-2-4,No.13 Road,Shenyang Economic And Technological Development Zone,Liaoning Province,China. +86-130 32458698 [email protected]

Material and process

Mini letters are commonly made of acrylic and stainless steel. Mini illuminated letters are characterized by their small size and exquisite shape, and various shapes and fonts ,and can be customized according to the customer's demand for a variety of shapes and fonts. Whether it is a simple style or gorgeous style, can be shown through the mini letters!

Features:

1、It looks clean and tidy, without glue edges and metal edges;

2、letters are small and can be made with small sharp strokes;

3、The area of the bottom of the mini letter is larger than the area of the face, and the three-dimensional effect is strong. The light-emitting area is more extensive, even at a distance, you can see the mini letter illuminated signs from all angles.

Application scenarios

It is mainly applied in indoor shopping malls, service halls, exhibition centers, corporate culture walls and other scenarios.

Backlit letter

Material and process

Backlit letter and wall separation, the led light source is installed behind the stainless steel letter shell panel, the word bottom with acrylic board translucent, to achieve the effect of Backlit. Make the Backlit in the light of the reflection is clearly visible, with better visual effect and durability.

Features

1、Good three-dimensional effect, stainless steel word seems to be floating in the light.

2、The light is soft and eye-catching, to the back of the light so that the light will not be straight to the eye

3、Long service life, with good weather resistance.

Application Scenario

Commonly used in shop front or corporate image wall, etc.

Borderless letters

Material and process

Borderless luminous letters, as the name suggests, "Borderless" is its biggest advantage, is a common, affordable cost of luminous letters.

The use of aluminium around the edge, the surface of the acrylic , the finished product of the letter view of the edgeless, very modern.

Features

1、Luminous surface is bigger, especially suitable for the font with fine strokes.

2、Aluminium enclosure is lighter and not rusty.

3、Cheap, exquisite appearance, suitable for close viewing

4、Size can not exceed 1.2 metres, or easy to crack.

5、Easy to maintain.

6、Will not crack, will not rust, is a dual-use indoor and outdoor light-emitting word

Application Scenario

Commonly used in shop front or corporate image wall, etc.

Edge-wrapped illuminated letters

Material and process

Stainless steel wrapped word using stainless steel cutting, welding, panel with acrylic, light source using energy-saving LED light strip!

Stainless steel wrapped word is a commonly used indoor and outdoor signage materials, processed from stainless steel plate, corrosion-resistant, durable, beautiful appearance.

Features

1. Sturdy and durable, metal texture, uniform light emission, energy saving and environmental protection.

2. Strong sense of three-dimensionality.

3. Waterproof and moisture-proof.

4. Beautiful during the day, bright at night, giving people a high-grade feeling.

Application Scenario

Commonly used in shop front or corporate image wall, etc

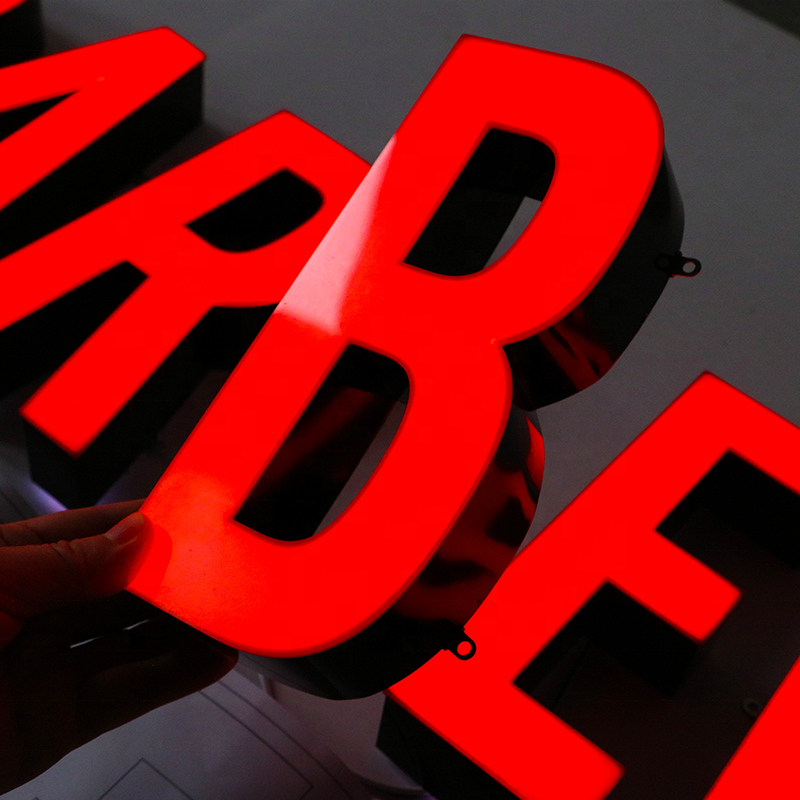

Resin illuminated letters

Material and process

Resin illuminated letters is a kind of processing technology, the main principle is to spread the plastic hard sheet heating and softening, using vacuum adsorption on the surface of the mould, after cooling and forming.

Features

1、The word panel is a raised form surface with good visual effect.

2、The production cycle is long and the process is complicated.

3、In addition to single-layer plastic word, there are double-layer plastic word, multi-layer plastic word multi-layer plastic word each plastic layer of different colours, layer by layer, showing a strong sense of three-dimensionality and hierarchy.

Application Scenario

1、Suitable for all kinds of outdoor advertising letters, mainly suitable for the production of larger (more than one metre high), thicker strokes of the font.

2、Suitable for shop signboards and image wall.

Super letters

Material and process

Also known as liquid acrylic light-emitting characters, is specially developed for the shortcomings of resin characters. The shape is similar to the word without edges, using aluminium or stainless steel around the edge of the word frame, the surface of the pouring liquid acrylic adhesive cured at room temperature and become.

Features

1、The word surface rounded full, seamless integration, sharp edges and corners, strong sense of three-dimensionality;.

2、With the weather resistance of acrylic material and cost-effective, not easy to crack.

3、Indoor and outdoor universal, improve the resin word easy to yellow oxidation shortcomings.

4、Awide range of sizes, the minimum English can be done 15CM, the minimum Chinese can be done 20CM, the maximum can be done 1.5 metres, as long as the bending machine can be bent out of the word can be produced; this limit, the other light-emitting word is very difficult to do so.

Application Scene

Mainly used in shopping malls, offices, background walls, store front signboard and other scenes

Punched letters

Material and process

The use of machine tools will be sheet (galvanised sheet, stainless steel) punched into the same size, rows of small holes, installed single waterproof LED light beads, from the surface of the exposed light beads can be seen, so it is also known as "exposed light beads light-emitting letters".Light-emitting effect is better, LED string light can be sent monochrome (common red, yellow, white three), seven-colour, full-colour and other different effects of light.

Features

1、 Perforated light-emitting letters can be done in large letters, without size limitations;

2、Strong weather resistance, energy saving, power saving, small power consumption, only one-tenth of the traditional neon lights, and for the weak electricity is very safe.

3、Visual impact and strong brightness, can be seen thousands of metres away

4、Exposed light-emitting word by colour is divided into monochrome, seven-colour, full-colour light-emitting word.

(1) Single-colour light-emitting letters is made of punched holes in the word shell and single-colour leakage lamps.

(2) Seven-colour exposed letter is made up of punched holes in the letters shell and seven-colour leakage lamp seven-colour controller, after the light can be seven-colour gradient;

(3) Full-colour exposed light-emitting letters by punching a good hole in the word shell and full-colour leakage lamps, full-colour controller, the use of professional software to create program files into the SD card, SD card inserted into the full-colour controller, after the light leakage of light-emitting word can be played in flash animation, character animation, the effect of the very high grade.

Application Scene

Mainly used in shop signboards, bars, hotels, hotels and other entertainment venues signboards, etc.

Light bulb letters

Material and process

Light bulb letter is a retro craftsmanship illuminated letter, usually made of baked metal for the base wrapping, and ball-shaped lamps or tungsten lamps composition. The different spacing and density of the lamps will affect the overall price of the letter.

Features

1、Evenly luminous, high beam brightness.

2、Strong weather resistance, the base plate and bulb will do waterproof treatment accordingly.

3、Easy maintenance, bulbs are independent of each other, can be replaced individually.

4、The word is not limited by the size can be customised according to customer requirements.

Application Scene

Mainly used in wall decoration, outdoor shopping mall landscape, etc.